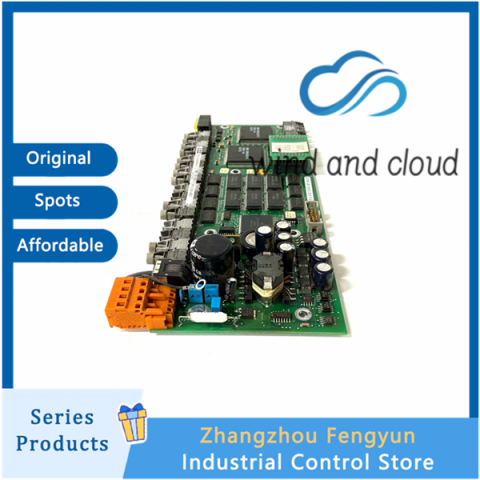

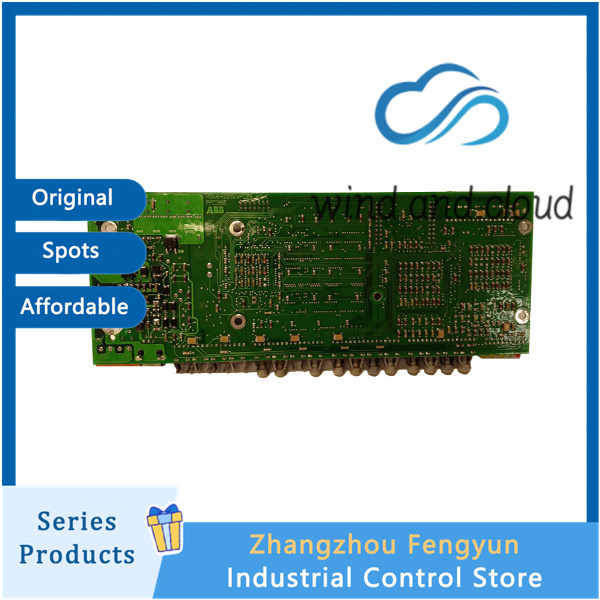

All products on this website are discounted products, and market prices have been fluctuating. Please refer to customer service quotes for details. Pictures are not actual photos. Before placing an order, please confirm the model, product, price, and other detailed information with customer service. Both second-hand and brand new products are available for sale on this website. Please contact customer service for further communication.

ABB PPC380AE102 HIEE300885R0102|Servo Control Module|

The module is equipped with a high-speed industrial-grade processor and supports advanced motion control algorithms, enabling high-precision triple-loop control of position, speed, and torque.

This makes it suitable for high-speed motion equipment requiring extremely fine accuracy—for example, achieving micrometer-level positioning in CNC and machine-tool applications to ensure machining precision.

With integrated digital signal processing (DSP) capabilities, the system can quickly analyze multi-type sensor inputs such as temperature, pressure, and vibration, while supporting parallel multitask control for complex, multi-axis or multi-device coordination scenarios.

Storage Adaptation

Based on the configuration architecture of the PPC380AE01 model in the same product line, this module is expected to include a combination of RAM + Flash optimized for industrial control.

This storage configuration ensures stable program execution and reliable preservation of real-time operational data, without dependence on frequent external storage access, thereby enhancing long-term continuous operation capability.

Key Physical and Electrical Parameters

(Predicted based on common PPC380 series specifications and adaptation characteristics)

Parameter Type Typical Value

Input voltage 10–30 V DC

Output voltage 24 V DC

Operating temperature –25 ℃ to +70 ℃

Storage temperature –40 ℃ to +85 ℃

Dimensions ≈ 150 mm × 70 mm × 130 mm

Weight ≈ 0.5 kg

These parameters allow stable operation under standard industrial environmental conditions.

Core Functional Advantages

1. Multi-Mode Control Adaptation

The system supports three fundamental control modes:

Position control

Speed control

Torque control

Users can flexibly switch between modes according to equipment requirements.

Examples:

Packaging machinery: speed control ensures smooth and consistent conveyor motion.

Robot joint drives: torque control protects mechanical components during load changes.

This versatility makes the module highly adaptable to diverse automation scenarios.

2. Flexible Communication and Expansion

Equipped with multiple communication options such as Ethernet and CAN bus, the module enables seamless data exchange with PLCs, sensors, actuators, and other field devices.

It also supports integration with third-party industrial systems, enhancing system interoperability.

Based on typical series characteristics, the module is also likely to support multi-channel analog inputs, enabling synchronous acquisition of multiple device signals for centralized, coordinated control.

3. High Reliability

Manufactured using industrial-grade high-quality components, the module complies with stringent industrial environmental standards. It offers resistance to:

Oil contamination

Electromagnetic interference (EMI)

Temperature fluctuations

Mechanical vibration

Its stable operating characteristics reduce equipment failure rates, ensure continuous production line uptime, and significantly lower maintenance downtime and operating costs.

ABB PPC380AE102 HIEE300885R0102|Servo Control Module|

Hot selling models

By structuring the information in this manner, the article provides a clear and organized understanding of input channels, transducer supply, and communication implementations in distributed control systems.

Zhangzhou Fengyun’s main products include ABB, GE, Bently Nevada Bentley, ICS TRIPLEX, Honeywell, Schneider, EPRO, yokogawa Yokogawa, Woodward, EMERSON, Emerson, and Invensys TRICONEX, which have abundant inventory, fast delivery, and reliable quality.

.jpg)

There are no reviews yet.