AAll products on this website are discounted products, and market prices have been fluctuating. Please refer to customer service quotes for details. Pictures are not actual photos. Before placing an order, please confirm the model, product, price, and other detailed information with customer service. Both second-hand and brand new products are available for sale on this website. Please contact customer service for further communication.

Modules: Input/output elements housed in a casing, compatible with the PCD1/2 system.

Module holders: Devices such as CPUs, RIOs, or LIOs, to which modules can be attached.

Overview Section

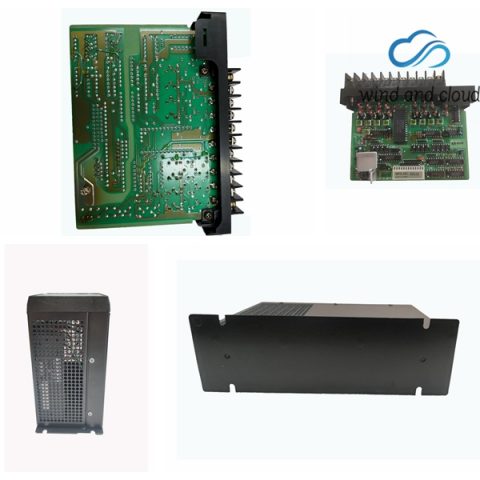

SAIA PCD4.H440|Programmable Logic Controller|

Key Features

High-Performance Computing Core

32-bit high-performance industrial CPU supports true multitasking (up to 16 tasks). Simultaneously runs logic control, PID process adjustment, data acquisition, and protocol parsing with real-time responsiveness (basic instruction execution time ≤ 0.5 µs).

Full-Function Modular Expansion

CPU module is completely separated from I/O, communication, and special-function modules (high-speed counting, motion control, etc.), enabling large-scale I/O expansion and custom functionality without bottlenecks.

Industrial-Grade High Reliability

Wide-temperature design (–25 °C to +70 °C), EMC compliance (IEC 61000-6-2/6-4) and vibration resistance (IEC 60068-2-6). Suitable for harsh environments such as industrial workshops and outdoor control cabinets.

Integrated Multi-Protocol Communication

Multiple built-in industrial interfaces allow mainstream bus and Ethernet communication without additional modules. Enables cross-system data exchange with SCADA, MES, and upper-level systems.

Security & Redundancy Support

Select models support redundant power modules, program backup/recovery, online firmware updates, reducing downtime risk and improving system availability.

Category-Specific Specifications

Core Performance

Processor: 32-bit industrial CPU, multitasking scheduler (max. 16 tasks), ≤ 0.5 µs basic instruction time

User Memory: 2 MB standard (program + data); expandable to 8 MB Flash for backups/historical data

Real-Time Clock: Built-in RTC with lithium battery backup, ±30 s/month; supports NTP synchronization (Ethernet required)

I/O Expansion Capability

Central I/O Points: Up to 1024 (PCD4 dedicated I/O modules)

Remote Expansion: Profibus DP, Modbus RTU/TCP, CANopen (master/slave), up to 4096 remote I/O points

Supported Modules: DI/DO (standard/high-speed), AI/AO (16-bit), temperature (PT100/thermocouple with cold-end compensation), high-speed counting (up to 1 MHz), pulse output for step/servo (up to 500 kHz)

Integrated I/O Channels

Digital: 16 DI (24 VDC, PNP/NPN configurable, supports interrupts) + 8 DO (24 VDC, 1 A/point, supports PWM)

Analog: 8 AI (4-20 mA/0-10 V, configurable ±10 V or thermocouple, 16-bit resolution) + 2 AO (4-20 mA/0-10 V, 16-bit)

Communication Interfaces

Serial Ports: 4 configurable RS-232/RS-485 (Modbus RTU, SAIA PCD Link, ASCII)

Industrial Bus: Built-in Profibus DP master/slave (DP-V1), CANopen master/slave (DS301/DS401)

Ethernet: 2 integrated Gigabit ports (TCP/IP, Modbus TCP, EtherNet/IP, PROFINET IO slave; optional PROFINET IO master module)

Other: Supports expansion to Profinet, EtherCAT, Modbus TCP master modules to fit various network architectures

Special Functions

Motion Control: 2-axis pulse motion (point control, linear interpolation); expandable to 4-axis with dedicated module

Process Control: 32 built-in PID loops (self-tuning, feed-forward, adaptive closed-loop regulation of temperature, pressure, flow)

Data Recording: Historical data storage with SD card module, configurable period 1 ms–1 h for trend analysis and fault tracing

Safety Function: Optional safety module (PCD4.SAFE) supports SIL 2 safety level for emergency stop, safety door monitoring, etc.

SAIA PCD4.H440|Programmable Logic Controller|

Physical & Certification

| Parameter | Value |

|---|---|

| Installation | DIN-rail, approx. 120 × 140 × 90 mm (W×H×D) |

| Protection Level | IP20 (install inside closed control cabinet) |

| Certifications | CE, UL, CSA, ATEX (hazardous areas), RoHS compliant |

By structuring the information in this manner, the article provides a clear and organized understanding of input channels, transducer supply, and communication implementations in distributed control systems.

Zhangzhou Fengyun’s main products include ABB, GE, Bently Nevada Bentley, ICS TRIPLEX, Honeywell, Schneider, EPRO, yokogawa Yokogawa, Woodward, EMERSON, Emerson, and Invensys TRICONEX, which have abundant inventory, fast delivery, and reliable quality.

.jpg)

.jpg)

-480x480.jpg)

There are no reviews yet.