AAll products on this website are discounted products, and market prices have been fluctuating. Please refer to customer service quotes for details. Pictures are not actual photos. Before placing an order, please confirm the model, product, price, and other detailed information with customer service. Both second-hand and brand new products are available for sale on this website. Please contact customer service for further communication.

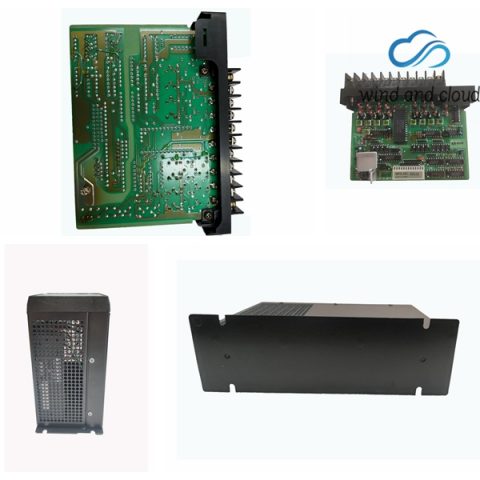

SAIA PCD4.H420|Programmable Logic Controller|

Key Features

Mid to High Computing Performance

Equipped with a 32-bit industrial-grade CPU supporting multitasking parallel processing (logic control, data acquisition, communication protocol parsing). Basic instruction execution time ≤ 1 µs, ideal for moderately complex scenarios such as multi-loop PID regulation and high-speed counting.

Flexible Scalability

CPU module separated from I/O, communication, and special-function modules. Digital, analog, and temperature acquisition modules can be expanded on demand without bottlenecks, balancing current needs with future upgrades.

Industrial-Grade Stability

Wide temperature range (–25 °C to +70 °C), EMC compliance (IEC 61000-6-2/6-4), vibration resistance (IEC 60068-2-6). MTBF > 100 000 h makes it suitable for harsh workshops and outdoor control cabinets.

Mainstream Communication Integration

Built-in industrial communication interfaces allow direct connection to HMI, drives, and upper-level systems without extra modules. Expansion for high-end buses (PROFINET, EtherCAT) ensures compatibility with both legacy and new network architectures.

Basic Special Functions Built-In

Integrated PID process control, high-speed counting, and other functions support moderately complex control tasks (temperature closed-loop regulation, equipment positioning) without dedicated modules, reducing initial investment.

Key Technical Parameters

Core Performance

Processor: 32-bit industrial CPU, 8 priority tasks, ≤ 1 µs basic instruction time

User Memory: 1 MB standard (program + data); expandable to 4 MB flash for backup/historical data

Real-Time Clock: Built-in lithium battery backup RTC, ±1 minute/month; supports NTP synchronization (Ethernet required)

I/O Expansion Capability

Central I/O Points: Up to 512 (PCD4 dedicated I/O modules)

Remote Expansion: Profibus DP (master/slave) and Modbus RTU/TCP (master) for remote I/O; up to 2048 remote points

Supported Modules: Digital DI/DO (standard/high-speed up to 100 kHz counting), Analog AI/AO (12–16 bit), Temperature (PT100/thermocouple with cold-junction compensation)

Integrated I/O Channels

Digital: 12 DI (24 VDC, PNP/NPN configurable, supports interrupts); 6 DO (24 VDC, 0.5 A/point, PWM capable)

Analog: 6 AI (4–20 mA/0–10 V, software-configurable range, 12-bit); 1 AO (4–20 mA/0–10 V, 12-bit)

Communication Interfaces

Serial Ports: 3 configurable RS-232/RS-485 (Modbus RTU, SAIA PCD Link, ASCII) for HMI, instruments, drives

Industrial Bus: Built-in Profibus DP slave (optional module upgrade to master)

Ethernet: 1 × 100 Mbps port (TCP/IP, Modbus TCP; optional PROFINET IO slave module)

Extended Support: CANopen and EtherCAT modules optional to fit different industrial buses

Special Functions

Process Control: 16 built-in PID loops (self-tuning, feed-forward, adaptive closed-loop for temperature, pressure, flow)

High-Speed Counting: 2 integrated counters up to 50 kHz (pulse counting, frequency measurement, phase difference detection)

Data Recording: Supports SD card module for historical data storage (configurable 10 ms–1 h) for fault tracing/trend analysis

Event Recording: Automatic I/O status and fault log with time stamps for diagnostics

SAIA PCD4.H420|Programmable Logic Controller|

Physical & Certification

| Parameter | Value |

|---|---|

| Installation | 35 mm DIN rail; approx. 100 × 130 × 85 mm (W×H×D, per manual) |

| Protection Level | IP20 (install in closed control cabinet) |

| Certifications | CE, UL, CSA, RoHS; some versions support ATEX Zone 2 |

By structuring the information in this manner, the article provides a clear and organized understanding of input channels, transducer supply, and communication implementations in distributed control systems.

Zhangzhou Fengyun’s main products include ABB, GE, Bently Nevada Bentley, ICS TRIPLEX, Honeywell, Schneider, EPRO, yokogawa Yokogawa, Woodward, EMERSON, Emerson, and Invensys TRICONEX, which have abundant inventory, fast delivery, and reliable quality.

.jpg)

.jpg)

-480x480.jpg)

-480x480.jpg)

There are no reviews yet.