All products on this website are discounted products, and market prices have been fluctuating. Please refer to customer service quotes for details. Pictures are not actual photos. Before placing an order, please confirm the model, product, price, and other detailed information with customer service. Both second-hand and brand new products are available for sale on this website. Please contact customer service for further communication.

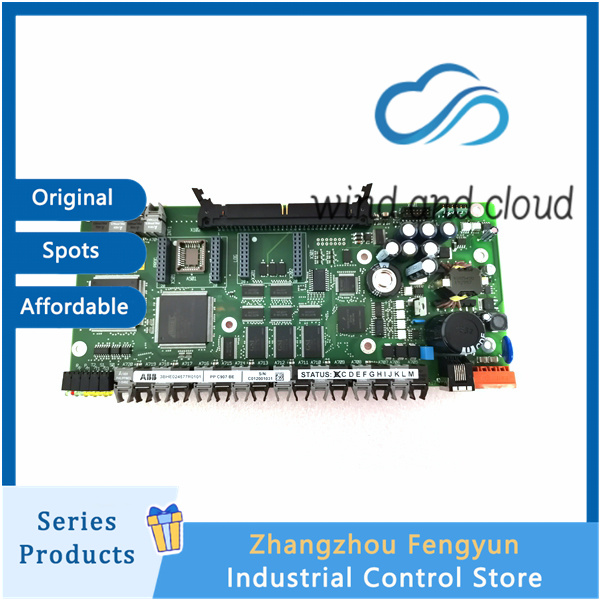

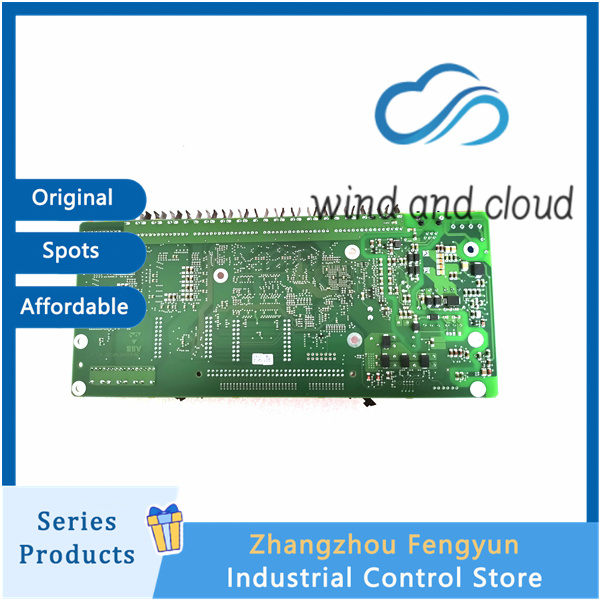

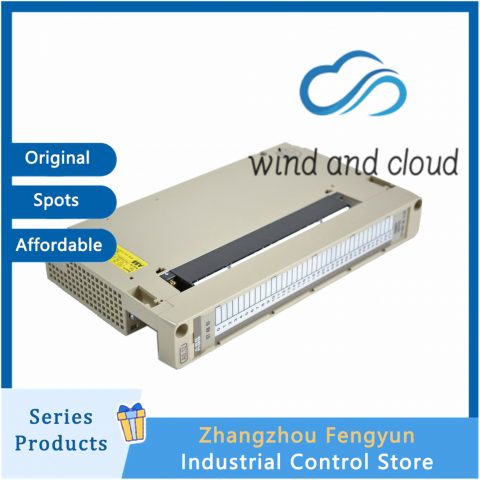

ABB PPC907BE101 3BHE024577R0101|Process Control Unit|

1. Rich I/O and Communication Capabilities

The controller integrates 8 digital input channels (DI) and 8 digital output channels (DO) as standard, and also supports analog signal acquisition and processing for comprehensive field-device interfacing.

The communication subsystem covers a wide range of industrial interfaces and buses:

EtherNet/IP

RS-232 / RS-485

PROFIBUS DP V1.0

CAN bus

It supports industrial protocols such as Modbus RTU/TCP and EtherNet/IP, with data transmission rates up to 12 Mbps, ensuring efficient communication with sensors, actuators, drives, meters, and third-party automation equipment.

2. Flexible Expansion and Adaptation

Supports up to 2048 I/O points

Compatible with ABB S800/S900 series modular I/O units for both digital and analog expansion

Adapts to varying control scales—from compact equipment to large-scale process plants

Maintains excellent interoperability with the broader ABB automation ecosystem, simplifying integration into existing DCS/PLC infrastructures

3. High-Reliability Redundancy Design

The controller adopts a modular, redundant architecture, allowing critical functions to fail over automatically if a module malfunctions.

This design ensures:

Continuous operation during partial hardware faults

Avoidance of process interruptions

Enhanced system availability in mission-critical environments such as power, petrochemical, and heavy manufacturing industries

4. Convenient Operation and Maintenance Features

Equipped with intuitive LED status indicators for rapid diagnosis of power, operation, and communication states

Supports multiple IEC 61131-3 programming languages (such as LD, FBD, ST, SFC)

Bundled with easy-to-use engineering tools for fast logic development, online debugging, parameter tuning, and firmware updating

These features significantly reduce maintenance time and improve engineering efficiency.

5. Typical Application Scenarios

The controller’s multi-scenario adaptability makes it suitable for a wide spectrum of industrial sectors:

Power & Energy

Substation automation systems

Distribution automation

Power plant auxiliary equipment monitoring and control

High-voltage motor control and protection

Petrochemical & Refining

High-voltage motor and VFD coordination

Temperature, pressure, and flow regulation in reactors and distillation units

Process interlocks and safety-related auxiliary control

Manufacturing & Discrete Industries

Automotive assembly and robotic production lines

Aerospace component manufacturing

General automation machinery and production cells

Infrastructure & Utilities

Water treatment and wastewater plants

Building HVAC and environmental control systems

Food and beverage production line automation

The controller’s adaptability, robust communication capabilities, and high reliability make it a versatile choice across both continuous and discrete manufacturing environments.

ABB PPC907BE 3BHE024577R0101|Process Control Unit|

Hot selling models

By structuring the information in this manner, the article provides a clear and organized understanding of input channels, transducer supply, and communication implementations in distributed control systems.

Zhangzhou Fengyun’s main products include ABB, GE, Bently Nevada Bentley, ICS TRIPLEX, Honeywell, Schneider, EPRO, yokogawa Yokogawa, Woodward, EMERSON, Emerson, and Invensys TRICONEX, which have abundant inventory, fast delivery, and reliable quality.

There are no reviews yet.