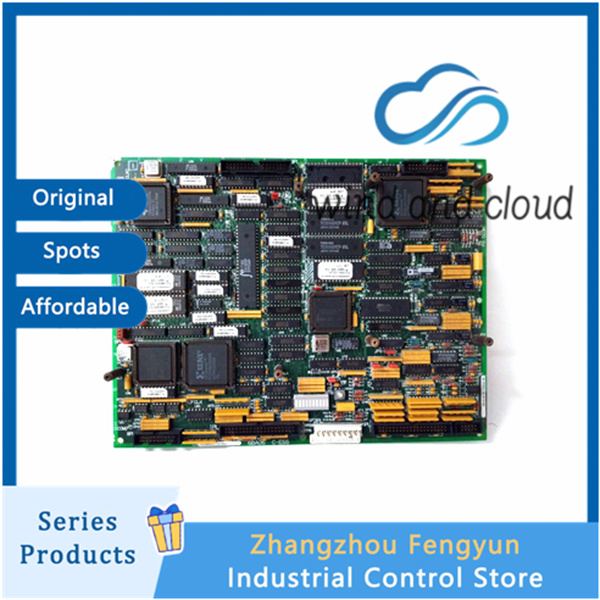

All products on this website are discounted products, and market prices have been fluctuating. Please refer to customer service quotes for details. Pictures are not actual photos. Before placing an order, please confirm the model, product, price, and other detailed information with customer service. Both second-hand and brand new products are available for sale on this website. Please contact customer service for further communication.

GE DS200SDCCG4AFD|Drive Control Card|

Processor and Storage Architecture

Equipped with three dedicated microprocessors responsible for drive logic execution, signal processing, and I/O management.

Supports parallel access to shared RAM, enabling coordinated multi-processor operation and high real-time performance.

Uses 4–5 EPROM/Flash memory devices (U7–U11) to store system configuration data and drive control programs.

During board replacement, the original memory devices must be transferred to the new board to retain site-specific parameters.

Incorporates a hardware watchdog circuit to monitor processor activity and automatically initiate a reset under abnormal operating conditions.

Interfaces and Connections

Provides multiple onboard connectors compatible with terminal boards, I/O expansion cards, and communication interfaces.

Supports transmission of analog (4–20 mA), digital, and servo valve drive signals, ensuring flexible integration with field devices.

Includes jumper configuration options (Berg-type or wired jumpers) for:

Factory testing

User-selectable functional adaptations, such as signal range settings and communication protocol selection.

Features LED status indicators for visual diagnostics of:

Power status

Processor operation

Communication activity

Physical Characteristics and Power Requirements

Form factor: Standard GE Mark V card size, fully compatible with system rack card slots.

Weight: Approximately 0.8–1.0 kg.

Power supply: 24 VDC nominal.

Operating temperature range: –40 °C to +70 °C, suitable for harsh industrial environments.

Core Functions and Typical Applications

Primary Drive Control

Implements closed-loop control of turbine speed, torque, and excitation.

Generates drive signals for servo valves and actuators within the turbine control loop.

Signal Conditioning and Processing

Conditions and processes 4–20 mA analog signals, digital inputs/outputs, and feedback signals such as LVDT and thermocouples.

Ensures high signal accuracy, stability, and immunity to electrical interference.

Configuration and System Adaptation

Stores customer-specific configuration parameters in EPROM/Flash memory.

Supports on-site reprogramming to accommodate different turbine types and operating conditions.

Diagnostics and Fault Detection

Built-in hardware and software diagnostic mechanisms.

Identifies faults related to processors, memory devices, or communication links using LED indicators and system alarm reporting.

Typical Applications

EX2000 series drive controllers, widely used in gas and steam turbine drive control systems.

Commonly operates with associated grid drive and I/O boards such as DS200GLAA, DS200LDCCH, and related modules.

GE DS200SDCCG4AFD|Drive Control Card|

Hot selling models

By structuring the information in this manner, the article provides a clear and organized understanding of input channels, transducer supply, and communication implementations in distributed control systems.

Zhangzhou Fengyun’s main products include ABB, GE, Bently Nevada Bentley, ICS TRIPLEX, Honeywell, Schneider, EPRO, yokogawa Yokogawa, Woodward, EMERSON, Emerson, and Invensys TRICONEX, which have abundant inventory, fast delivery, and reliable quality.

There are no reviews yet.