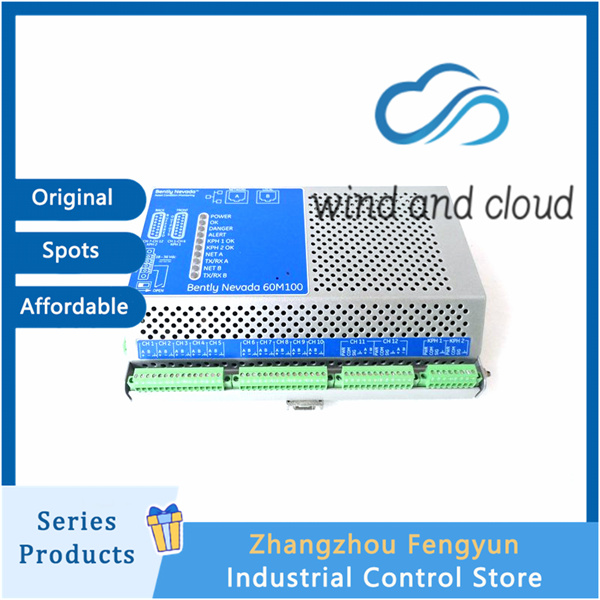

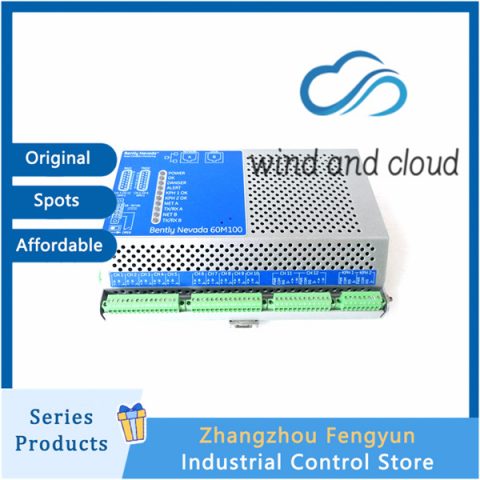

All products on this website are discounted products, and market prices have been fluctuating. Please refer to customer service quotes for details. Pictures are not actual photos. Before placing an order, please confirm the model, product, price, and other detailed information with customer service. Both second-hand and brand new products are available for sale on this website. Please contact customer service for further communication.

Bently Nevada 60M100-00|Condition Monitoring System|

Technical Specifications

Measurement channels

Supports up to 12 dynamic signal channels and 2 Keyphasor channels

Signal acquisition

24-bit Σ-Δ ADC

Sampling rate: 102.4 kS/s

Dynamic range: 110 dB

Bandwidth: 0–40 kHz

Sensor compatibility

Supports eddy current probes, vibration acceleration/velocity sensors, and temperature sensors, compatible with mainstream industrial signal standards

Power supply and consumption

Supply voltage: 18–36 V DC

Maximum operating current: 1.7 A

Surge current: 2.7 A (< 5 ms)

Communication interfaces

Dual independent Ethernet ports, supporting Modbus TCP/IP, suitable for remote monitoring and high-speed data upload

Core Functions and Application Value

Dedicated monitoring for wind turbine drivetrains

Specifically designed for key power-train components such as gearboxes, bearings, and main shafts. Advanced algorithms extract characteristic features to provide early warning of wear, imbalance, misalignment, and other developing faults.

Flexible deployment architecture

Can operate as a standalone monitoring unit or be integrated into wind power SCADA / DCS systems, supporting distributed acquisition and centralized condition monitoring.

High-reliability data acquisition

Designed for wide operating temperature and voltage ranges with strong resistance to vibration and mechanical shock, making it suitable for harsh wind farm environments.

Typical Application Scenarios

Wind power industry

Drivetrain condition monitoring and health management of wind turbines

Oil and gas / petrochemical industry

Condition monitoring of compressors, turbines, and critical rotating machinery

Power industry

Status monitoring and early fault warning for auxiliary power equipment

Bently Nevada 60M100-00|Condition Monitoring System|

By structuring the information in this manner, the article provides a clear and organized understanding of input channels, transducer supply, and communication implementations in distributed control systems.

Zhangzhou Fengyun’s main products include ABB, GE, Bently Nevada Bentley, ICS TRIPLEX, Honeywell, Schneider, EPRO, yokogawa Yokogawa, Woodward, EMERSON, Emerson, and Invensys TRICONEX, which have abundant inventory, fast delivery, and reliable quality.

There are no reviews yet.