All products on this website are discounted products, and market prices have been fluctuating. Please refer to customer service quotes for details. Pictures are not actual photos. Before placing an order, please confirm the model, product, price, and other detailed information with customer service. Both second-hand and brand new products are available for sale on this website. Please contact customer service for further communication.

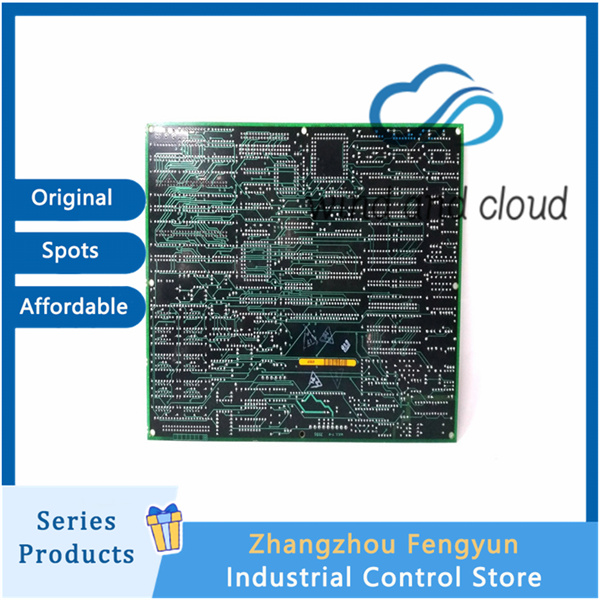

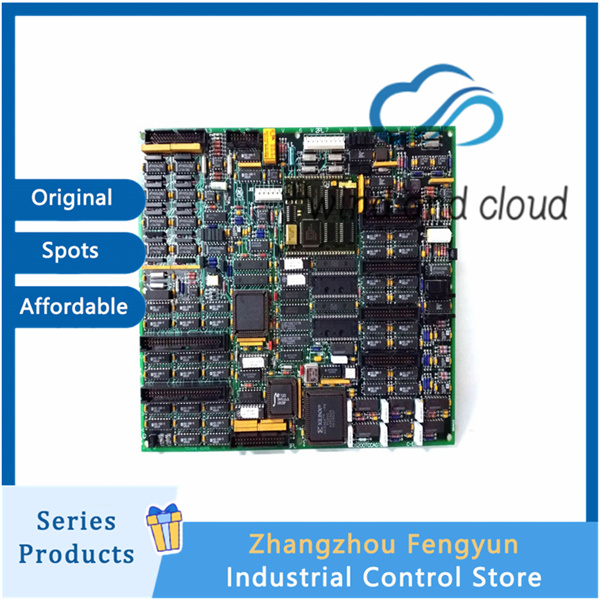

GE DS200TCCAG1B|TC2000 Analog I/O Board|

Signal Processing and Configuration

Supported Signal Types

Analog I/O: 4–20 mA input and output

Temperature inputs:

RTD (platinum resistance)

Thermocouples (Type K / J / T)

Electrical measurements: Shaft voltage and shaft current signals

Designed for acquisition of turbine temperature, pressure, vibration, and shaft-related parameters.

Processing Hardware

Based on an Intel 80196 microprocessor with multiple PROM firmware modules.

Handles A/D and D/A conversion, digital filtering, and signal range scaling.

Onboard programmable logic devices (PLDs) support deterministic timing and real-time signal processing performance.

Jumper Configuration

J1: RS-232 enable/disable selection

JP2: Test oscillator enable switch

JP3: Factory test–specific configuration

Jumpers are used for debugging, testing, and functional mode selection.

Interfaces and Status Indication

Backplane and Board Interfaces

Two 50-pin connectors (JCC / JDD) interface with the R5 core backplane.

3PL connector links to the STCA board, forwarding conditioned signals to the main control processor.

Debug and Configuration Interface

RS-232 serial port (enabled via J1 jumper).

Supports:

Firmware upgrade

Parameter configuration

On-site fault diagnosis

Status Indication

Single side-mounted LED indicator for rapid identification of:

Power supply status

Communication activity

Signal processing faults

Physical Characteristics and Power Requirements

Form factor: Standard Mark V R5 core card

Dimensions: Approximately 165 mm × 105 mm × 40 mm

Weight: Approximately 0.9–1.1 kg

Power supplies:

+5 VDC (logic and processor regulation)

±15 VDC (analog signal conditioning)

Operating temperature: –40 °C to +70 °C

Isolation rating: 500 VDC withstand between input, output, and power supply circuits

Core Functions and Typical Applications

Centralized Analog Signal Processing

Receives field signals from CTBA / TBQA / TBCA terminal boards located in the R5 core area.

Performs filtering, isolation, and A/D conversion.

Forwards processed data to the STCA board via the 3PL interface, which then synchronizes data with the main control card.

Control Command Output

Converts digital control commands from the main controller into 4–20 mA analog outputs.

Drives field actuators such as fuel valves and servo valves.

Firmware and System Configuration

PROM devices store fixed control logic and application firmware.

RS-232 interface allows on-site parameter adjustment and firmware updates to match different turbine operating conditions.

Typical Applications

GE Mark V gas and steam turbine control systems, specifically within the R5 core area.

Commonly paired with:

DS200STBAG1A (Drive Terminal Board)

DS200SIOBH1ABA (Analog I/O Board)

Used for temperature monitoring, pressure closed-loop control, and shaft condition diagnostics.

GE DS200TCCAG1B|TC2000 Analog I/O Board|

Hot selling models

By structuring the information in this manner, the article provides a clear and organized understanding of input channels, transducer supply, and communication implementations in distributed control systems.

Zhangzhou Fengyun’s main products include ABB, GE, Bently Nevada Bentley, ICS TRIPLEX, Honeywell, Schneider, EPRO, yokogawa Yokogawa, Woodward, EMERSON, Emerson, and Invensys TRICONEX, which have abundant inventory, fast delivery, and reliable quality.

There are no reviews yet.